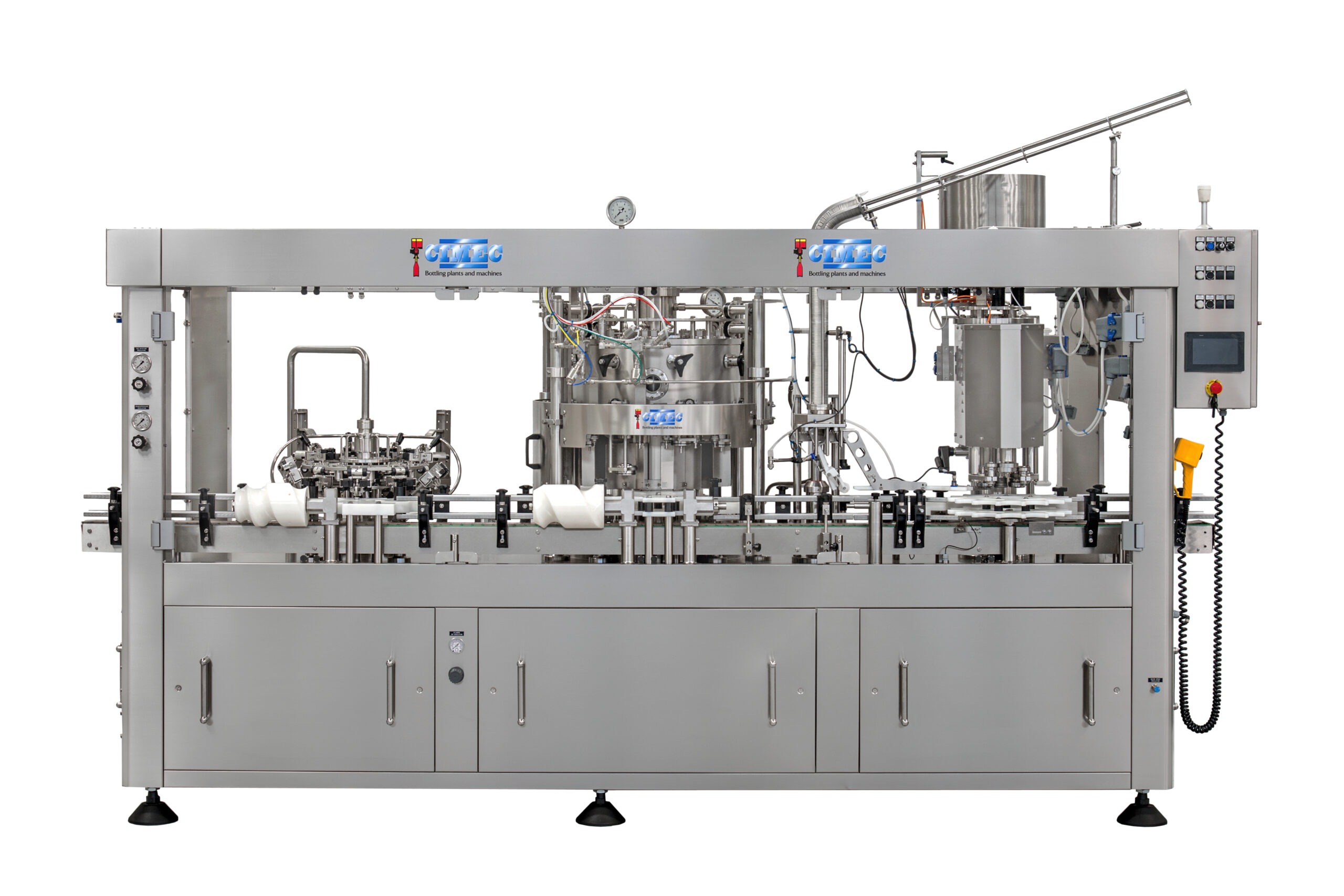

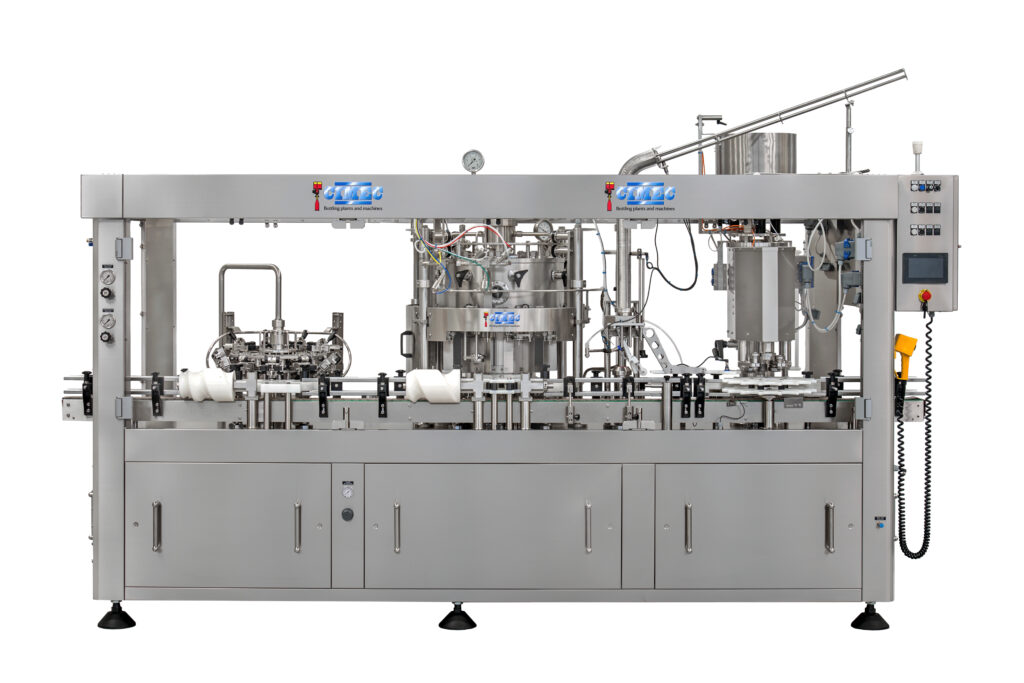

Cimec has designed and built a new filling monoblock capable of handling both glass bottles and aluminium cans consisting of:

- a single-treatment rinsing turret (water/air), equipped with a double-pad gripper capable of handling both bottles and cans without requiring any format changeover;

- an isobaric filling turret featuring double pre-evacuation/gas injection prior to bottle filling; alternatively, it is designed to perform a gas flushing cycle before can filling. This purging system protects the product from contamination caused by premature oxidation and ensures a longer shelf life;

- a rotating single-head turret fitted with a crown capper and a can seamer; depending on the container to be processed (bottle or can), the turret can be rotated by 180 degrees to activate one unit or the other. When processing cans, a lid dispenser is installed at the filler outlet.

When properly equipped, the machine with the rotating single-head turret can achieve a production speed ranging from 700 to 2,800 containers per hour and represents the ideal solution for craft breweries or producers of cider, kombucha, soft drinks, RTD and CSD products who require a multifunctional machine to meet market demands.