The Linx UVG5 laser enables permanent marking on a wide range of materials, including delicate films and hard-to-mark rigid plastics, for fast and consistent code marking.

It can mark a series of human- and machine-readable codes, including 2D Data Matrix and QR codes (including GS1).

Linx UV laser technology sets the benchmark for high-performance laser coding in demanding applications.

The excellent performance of this coder allows higher production throughput, with marking speeds of up to 2.000 characters per second, and minimal thermal stress on substrates compared to CO2 and Fiber marking.

The Linx UVG5 laser reduces the risk of damage to sensitive materials such as plastics and films and enables highly visible, readable codes to support traceability requirements. Mark products of varying sizes on the same line with integrated focus shifting, avoiding the need to move the laser or make mechanical adjustments on the production line.

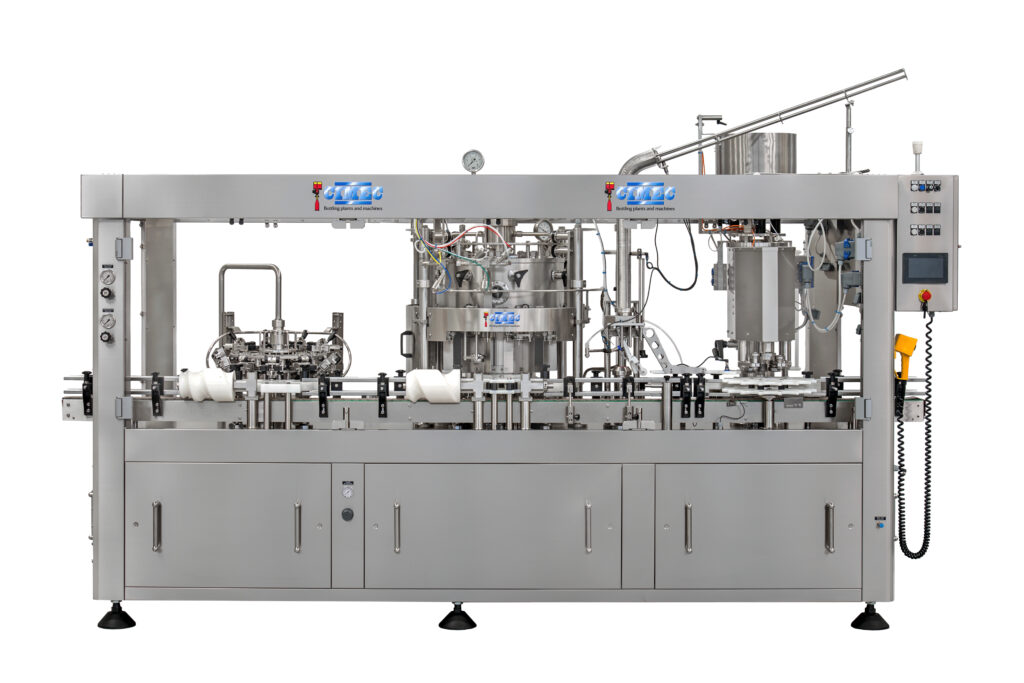

Integration into production lines is simplified thanks to various possible configurations.

The intuitive LinxVision user interface and the integrated Laser Pilot allow for more precise marking, resulting in fewer errors and reduced product waste.