Thanks to a perfect combination of technology, breadth of range and attention to the quality of the finished product, AROL solutions enable breweries of all sizes to confidently tackle the bottling stage, ensuring that every bottle reaches the consumer with the same characteristics defined by the master brewer

In the beer world, bottling is where technology, quality and brand identity converge. Whether it’s large international groups or independent breweries, the daily challenge is to ensure a reliable closure that preserves freshness, aromas and proper carbonation, offering consumers a consistent experience from the first to the last batch.

Beer culture is experiencing a new golden age: alongside historic brands, thousands of microbreweries have sprung up, each with its own interpretation of styles, raw materials and fermentation techniques. In this scenario, packaging is no longer just a container, but an essential part of the experience: whether it is a classic glass bottle, a special aluminium format or a plastic solution for more informal contexts, beer producers know how important it is to keep the sensory balance intact until the moment of opening.

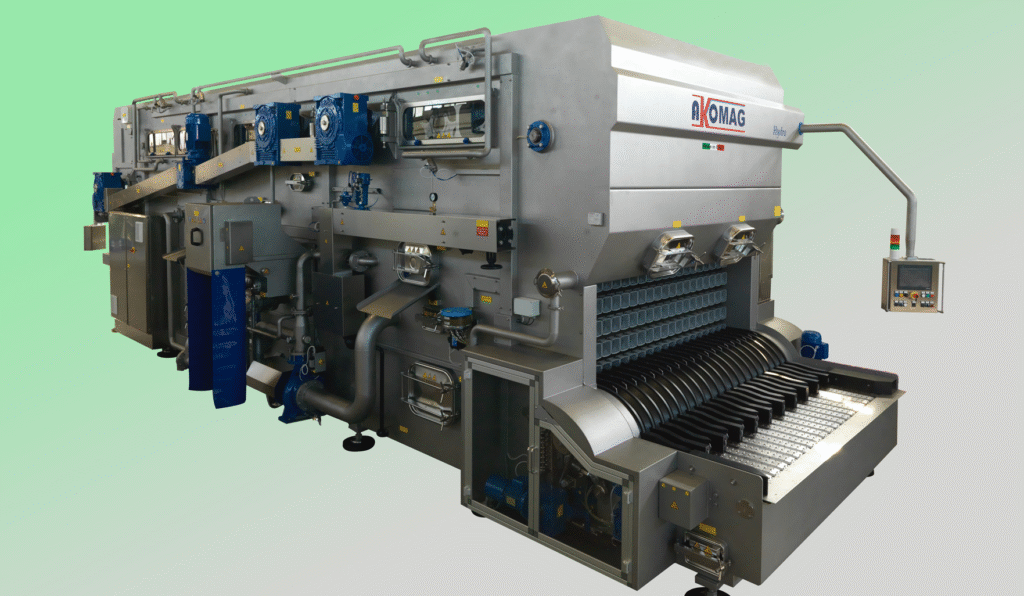

For over 45 years, AROL has been a global benchmark in the design and manufacture of capping and sealing machines, as well as cap feeding and orientation systems, with a range covering all the main closure requirements of the beer industry. The solutions range from the application of steel, aluminium or ring pull crown caps to the most sought-after cork, synthetic, aluminium or plastic caps, allowing each producer to adopt the configuration most consistent with their style, brand positioning and production volumes, without compromising on efficiency and reliability.

Committed to total quality and versatility

In this context, AROL provides technical solutions of the highest standard. The ESSE PK model is ideal for applying steel crown caps to glass, plastic or aluminium bottles, with speeds of up to 60,000 bottles/hour depending on the configuration. Its modular architecture facilitates integration into both high-capacity lines and smaller production plants, while ensuring high precision and repeatability of the process. The washable version, with stainless steel components and dedicated solutions for washing the capping area, fully meets the hygiene requirements of modern breweries.

For beers sealed with natural, agglomerated or synthetic corks, the QUASAR capping machine is the technological benchmark. Designed for use in a free-standing configuration or as an integrated in-line turret, it covers a wide production range, from small specialised businesses to large industrial lines with capacities of tens of thousands of bottles/hour. The dedicated suction system significantly reduces the amount of dust generated by corks, while specific washing solutions help to maintain a clean and controlled capping environment, in line with the most advanced standards in the industry.

Among the solutions that have marked the history of beer packaging, and which are still in demand today in specific markets, is the ring pull closure, for which AROL offers the dedicated ESSE RP version. For pre-threaded plastic or aluminium caps, the EURO family in the PK or VA version allows the application of plastic closures and aluminium screws on any type of container, offering high line versatility.

Alongside craft breweries

Particular attention is also paid to the world of craft breweries and microbreweries, which require compact but high-performance solutions. The single-head capping machines in the EAGLE family can be configured for the main types of closures, while the GEMINI one guarantees the correct application of cork, agglomerate and synthetic caps. For producers who need to handle multiple closures in small spaces, the DUAL solution integrates two types of capping into a single machine body, offering the necessary flexibility without compromising on quality.