The food & beverage packaging industry is now more than ever global, dynamic and innovation-driven. High performance, production flexibility, consistent quality and full process traceability are no longer differentiators, but essential requirements. In this highly competitive landscape, only a limited number of players can claim truly comprehensive expertise across the entire closure value chain.

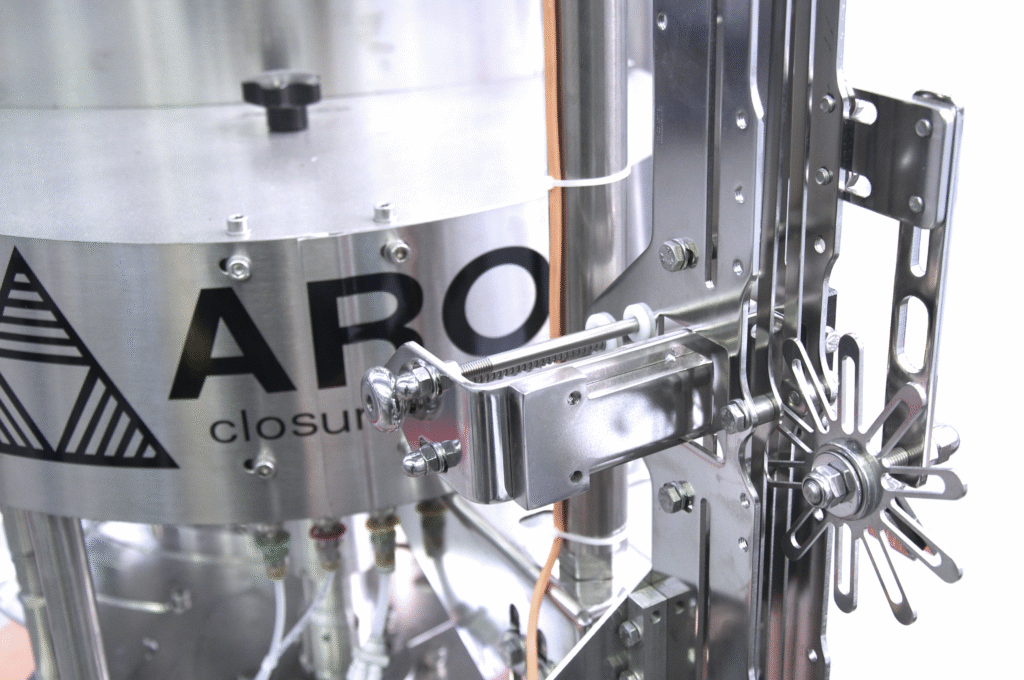

AROL is one of them. A global benchmark in capping systems, AROL stands out for a level of specialization that goes far beyond the standalone capping machine. Its added value lies in a systemic approach to closure application, strengthened by the integration with MACA Engineering and LAMFI Equipment, highly specialized companies in the design and manufacturing of machinery for plastic cap production and for the complete aluminum closure manufacturing process starting from metal sheet.

This synergy has created a unique industrial ecosystem capable of covering the entire closure lifecycle, from forming and processing to final application on the container. For customers, this means partnering with a single supplier possessing deep, cross-functional know-how of the capping process, developed both from the closure manufacturer’s perspective and from that of the bottler.

Expertise rooted in the closure

The presence of MACA and LAMFI within the AROL ecosystem represents a decisive strategic advantage. Both companies are internationally recognized for the engineering of equipment dedicated to plastic and aluminum closure production, working for years alongside leading closure manufacturers.

This proximity to the “closure world” enables AROL to develop capping solutions perfectly aligned with the technical specifications and evolving designs of different closure systems. It is not merely about applying a cap, but about understanding its geometry, materials, tolerances, mechanical behavior and functional requirements. This integrated expertise ensures high performance, scrap reduction and long-term operational reliability.

Around the capper: technology, control, value

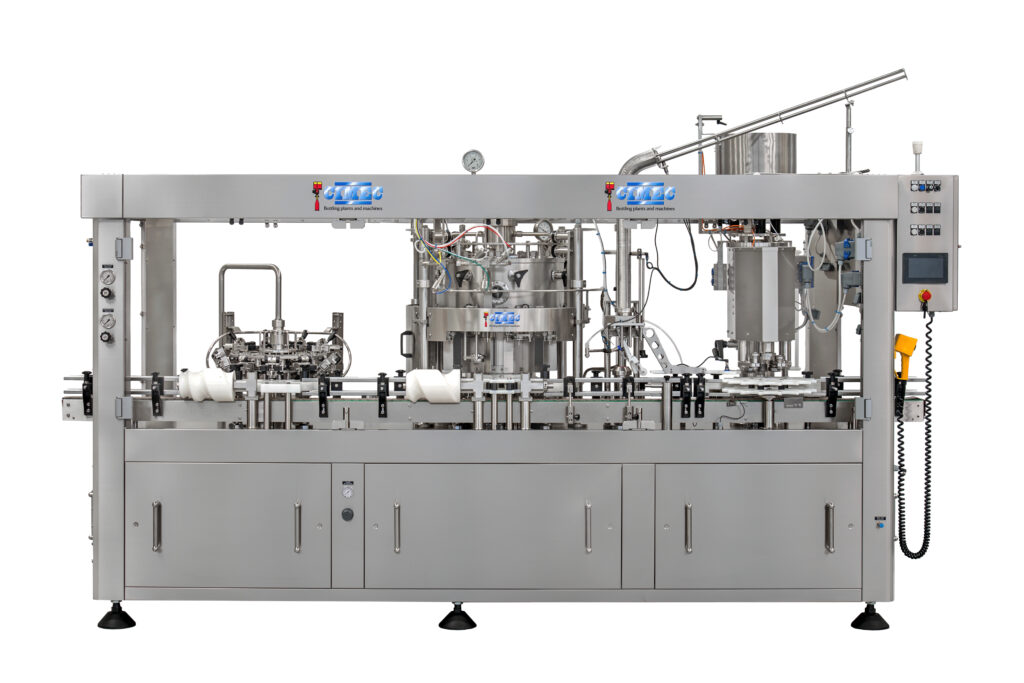

AROL represents the final integration point of the entire process. Its capping solutions are engineered to handle any container and virtually every closure type: screw caps, press-on caps, crown caps, corks, aluminum capsules and many other configurations across all major food & beverage segments.

However, excellence is not limited to the capping turret itself. The real differentiator is the “around the capper” approach: a suite of intelligent technologies designed to prepare, support and monitor every phase of the closure application process, ensuring consistent quality throughout the production cycle.

Cap orientation and feeding systems ensure that each closure reaches the capping station in the correct position and under optimal conditions. Upstream, washing, sanitizing and dust or microplastic reduction/removal modules can be integrated to meet the most stringent hygiene standards.

During and after application, advanced sensors and vision inspection systems verify in real time the correct placement of the closure, monitoring critical parameters such as torque, application height and integrity. The collected data are integrated into the MORE digital platform, a smart data environment dedicated to process monitoring and optimization.

MORE enables supervision not only of the capping operation but also of adjacent processes, ensuring full traceability, advanced analytics and detailed reporting. The integration of artificial intelligence algorithms further allows the detection of anomalous patterns and the prevention of process drift, transforming data into a tangible tool for continuous improvement.

In the era of smart packaging, this ability to combine precision mechanics with digitalization represents a concrete competitive advantage.

One partner, a complete vision

For food & beverage producers, choosing AROL means relying on a single partner capable of delivering an integrated system engineered to ensure maximum compatibility and seamless coordination between machines, closures and processes.

The combination of AROL’s capping expertise with MACA and LAMFI’s know-how in closure manufacturing machinery creates a pool of competencies that is extremely difficult to replicate. It is precisely this vertical integration that positions AROL as the ultimate expert in capping solutions: not simply a machine manufacturer, but a technology partner overseeing the entire closure value chain.

From closure manufacturing to final application on the container, AROL provides a comprehensive vision, cutting-edge solutions and full process control. An approach that transforms capping from a mere production step into a strategic driver of quality, efficiency and competitiveness.