In the food & beverage sector the lubrication of conveyor belts has always represented a crucial challenge for productivity, safety, and hygiene. The introduction of SUPEROIL FG and the dry lubrication system developed by AEB marks a technological turning point, capable of redefining the standards of efficiency, sustainability and reliability in modern bottling lines.

SUPEROIL FG is a transparent mineral lubricant, completely anhydrous, free of silicone and PTFE, specifically developed for dry lubrication of plastic conveyor belts for PET containers, laminated cardboard (TETRA), and cans, with full compatibility also for glass and food-grade metal alloys. Its ready-to-use formulation eliminates the need for dilution, ensuring maximum ease of use and drastically reducing the risk of operational errors.

From a chemical-physical standpoint, SUPEROIL FG presents itself as a transparent and odorless liquid, with pH 5.0 ± 0.5, density at 25 °C between 0.82 and 0.86 g/cm³, and viscosity at 20 °C between 180 and 210 cPs. These parameters ensure uniform distribution and lubricity even at high speeds, typical of modern bottling lines.

Compatibility is total with materials normally present in the food, cosmetic, and pharmaceutical industries, while the absence of water and surfactants eliminates the risk of foaming and cross-contamination. SUPEROIL FG is FDA certified 21 CFR 172.878 and 178.3620(a), as well as NSF H1, guaranteeing maximum food safety even in case of accidental contact with the product.

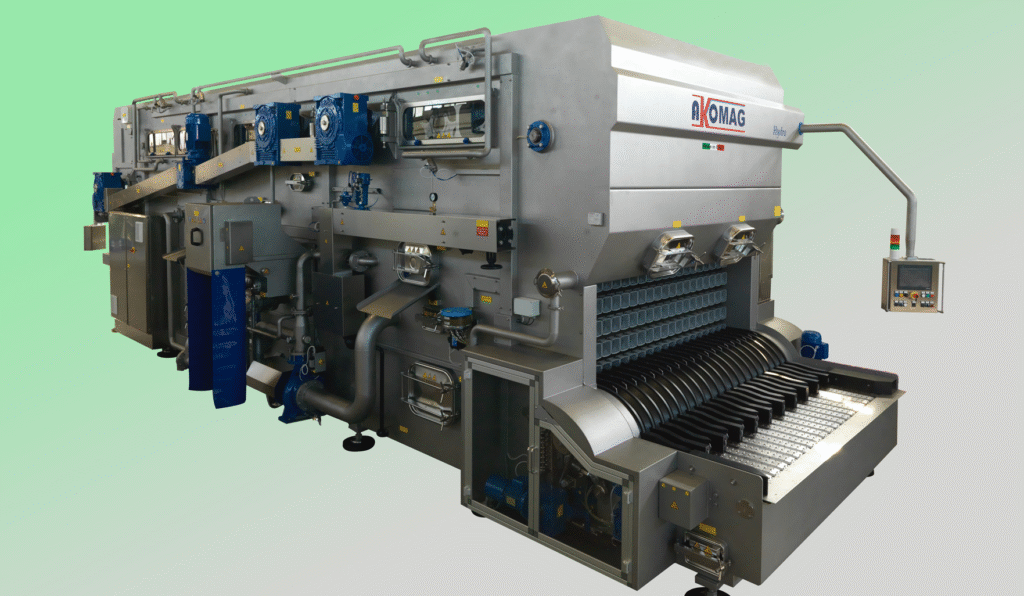

The AEB dry lubrication system: architecture and operation

The AEB dry lubrication system consists of a pumping unit with stainless steel tank, air/product distribution box, and a network of high-precision pneumatic dispensers, installed along the packaging line. Each dispensing point is independently adjustable, allowing optimal lubrication for each individual belt and easily adapting to long and/or complex lines.

Management occurs via Siemens PLC, with touch screen control panel that allows setting of parameters, cycles, and dispensing zones. The modularity of the system allows management from 6 up to 12 zones, ensuring maximum flexibility and scalability for every production need.

A distinctive aspect is the use of pneumatic nozzles instead of traditional brushes: this solution does not require periodic maintenance for brush replacement or cleaning, drastically reduces machine downtime, and allows immediate visual control thanks to transparent tubing. The entire system is designed to be compact, smart, and easily integrated at the line side, unlike the bulky structures typical of competing systems.

Productivity, safety and hygiene

L’adozione di SUPEROIL FG e dell’impianto dry AEB ha benefici tangibili su più livelli:

- zero water consumption: the total elimination of water in lubrication processes reduces operational costs, eliminates the need for effluent treatment, and contributes to environmental sustainability;

- reduction of energy consumption: the lower resistance to belt motion results in less load on drive motors and a consequent decrease in electricity consumption;

- extension of operational life: optimal lubrication reduces belt wear, extending their lifespan and reducing maintenance costs;

- application versatility: the system is compatible with complex configurations and high speeds, including lightweight bottles and inverted cans;

- dry surfaces and safety: the absence of water and foam keeps floors and surfaces dry, drastically reducing the risk of slipping and accidents for operators;

- microbiological control: the elimination of conditions favorable to bacterial growth improves the overall hygiene of the lines.

Environmental and economic benefits

The environmental impact of the SUPEROIL FG system is extremely reduced: the absence of water and the biodegradability of the lubricant minimize waste production and impact on purification systems. The reduction of CO₂ emissions, the elimination of organic loads, and the minimization of waste during production transitions contribute to a more sustainable production model compliant with the most stringent regulations.

From an economic standpoint, return on investment (ROI) is guaranteed by the reduction of operational costs (water, energy, maintenance), the elimination of effluent treatment costs, and increased productivity thanks to reduced machine downtime.

Compared to traditional water-based systems, SUPEROIL FG and the AEB dry system offer evident competitive advantages:

- application methodology: pneumatic nebulization with precision nozzles vs mechanical distribution with brushes;

- maintenance: maintenance-free nozzles vs mandatory monthly brush cleaning;

- diagnostics: transparent tubing for immediate visual control vs opaque tubing and difficulty identifying failures;

- architecture: compact and modular design vs bulky and complex structures;

- resource consumption: zero water consumption vs high water requirement for dilution;

- environmental safety: dry-condition surfaces vs wet environments at high risk;

- environmental impact: no effluent treatment required vs need for wastewater purification.

Case study: industrial validation

The industrial validation of the SUPEROIL FG system was conducted at one of the major Italian bottling plants, where the system operated continuously for months without interruptions, demonstrating full compatibility with high speeds, lightweight bottles, and complex configurations. The results showed substantial improvement in hygiene, drastic reduction in consumption, and greater operational reliability.

A strategic choice for the future of bottling

SUPEROIL FG and the AEB dry lubrication system represent a cutting-edge solution, capable of responding to the most critical needs of modern industry: efficiency, safety, sustainability, and regulatory compliance. The adoption of this technology not only improves productivity and reduces costs but actively contributes to the transition toward a more responsible and competitive production model.